AB Direct - Steers

Rail: 535.00-539.00 del

AB Direct - Heifers

Rail: 535.00-539.00 del

US Trade- Steers

Rail: 375.00-376.00 * few (IA, NE)

US Trade - Heifers

Rail: 375.00-376.00 * few (IA, NE)

Canadian Dollar

0.39

Hit peak carcass quality with Q-Sort

High feed costs and shortages mean feedlot owners face a tighter squeeze than ever. Helping them maximize their feed dollars by hitting the optimal market moment for their cattle is the goal of a genetic tool with an economic twist.

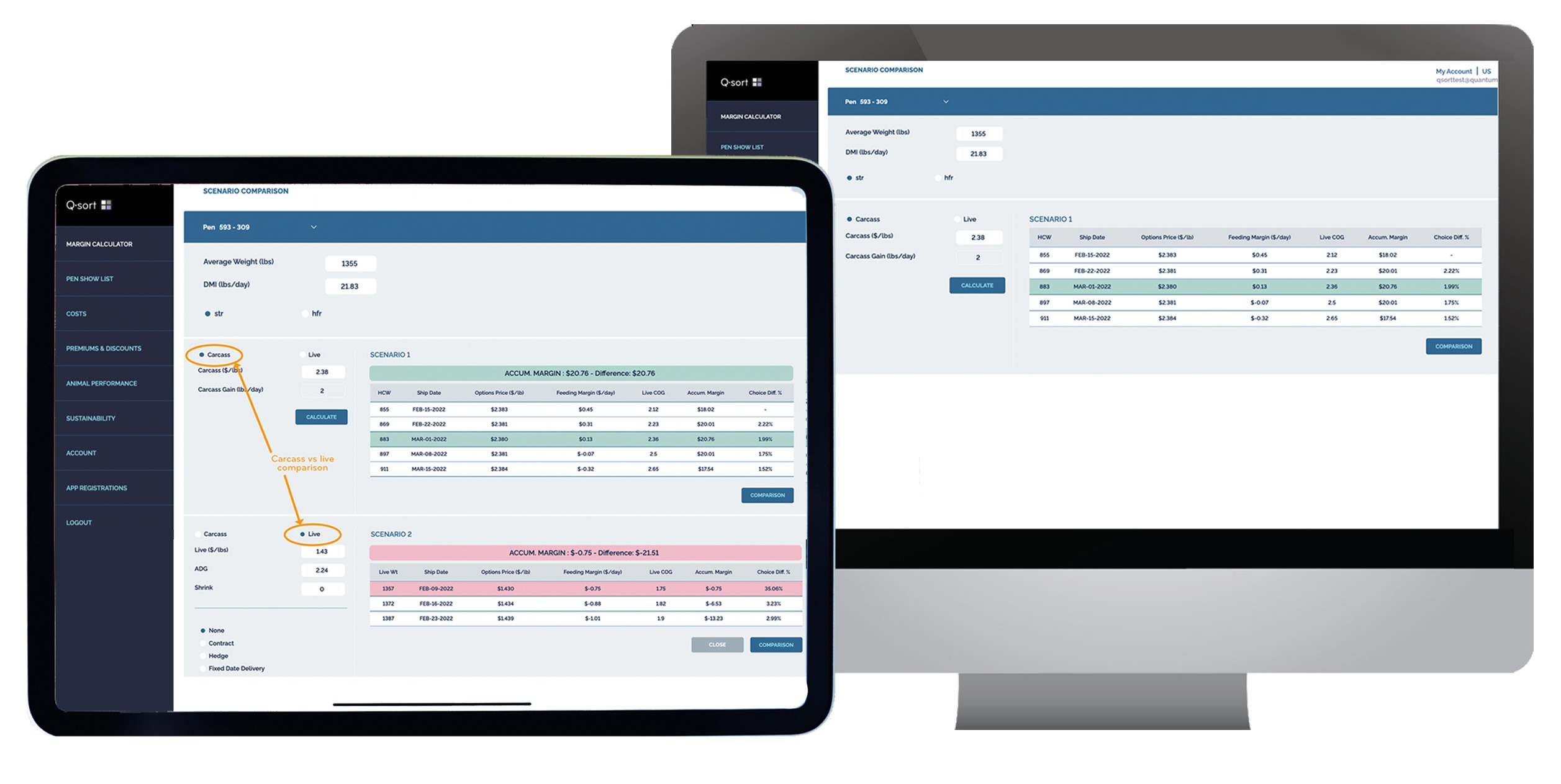

A program called Q-sort from Saskatoon-based Quantum Genetix provides data in a simplified form to reduce over or underfeeding, by linking feed program data with genetic predictors on carcass capability to come up with the optimum time to market a pen.

Quantum has been offering genomics services to the beef business since 2003, when it came up with a DNA test to identify genetic mutations impacting feed intake, which can have measurable benefits for carcass growth and composition. While there are implications for all aspects of the beef production cycle, Q-sort is tailored for feedlot operators and has undergone some reshaping, with its new approach introduced just recently.

“We’ve taken it into a whole new ballgame,” says Kirsty McCormack, Technical Sales Manager for Quantum Genetix.

After numerous feedlot trials with major cattle feeders across North America on more than 120,000 head of cattle, Q-sort has been finetuned and modified to feedlot realities. It syncs with current feeding software and combines it with the genetic data, and incorporates pricing fluctuations, as well as packer premiums and discounts, to come up with an easy-to-read assessment of whether there’s money being left on the table or it’s go time.

“Last year the biggest things feeders were asking themselves were: ‘when should I be selling these cattle? Are they getting too heavy? Should I be looking at the live market? What are my options, and what is the most profitable marketing opportunity for my cattle?’,” says McCormack, who worked in the Australian beef industry before coming to Canada.

“We know scientifically which animals will perform better on feed. Through genomic testing, we know the ratio of each pen so we see what their genetic performance will be. Coupled with all the research data we’ve done on carcass capabilities, we can accurately evaluate how the carcass is growing under the hide. So it’s like having a huge carcass calculator in the background to determine the feeding margin of your operation.”

While the original theory for maximizing genetic potential in the feedlot was for sorting the animals into pens according to carcass development type; in the real world that wasn’t as workable. Feedlot operators had their own pen sorting systems; by sex, producer of origin, or other factors. Once those pens are set, there wasn’t much of an appetite for resorting them several weeks later.

“In reality, managing it on a pen level has been more accessible,” says McCormack.

Q-sort also has a built-in pen show list, so if trucks are booked in, the pens can be ranked for which ones are ready, showing the feeding margin value left, along with the price they should be asking – since Canfax daily market data are also incorporated.

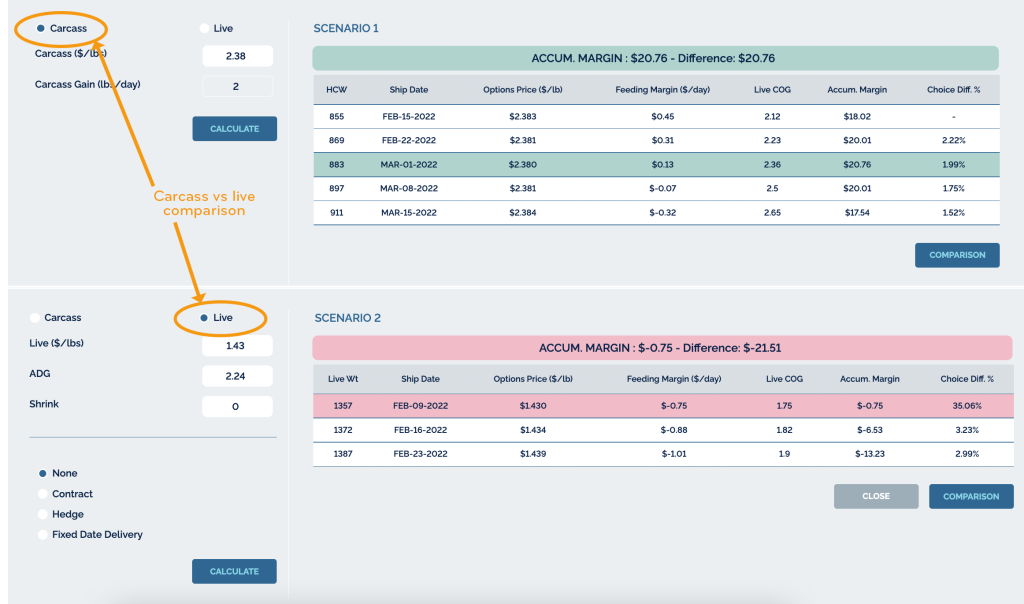

The program has also expanded to be able to do a comparison between the carcass price, and the live market one with shrink, taking into account hedges, fixed delivery dates or contracts.

“It’s how far can you push that animal before you get into the discount space and too heavy on the hook, but are still making money. It’s looking at what is the accumulated margin under the hide, and how much money is left in that animal to reach optimal hot carcass weight.”

“The biggest pain point we found in industry when you talk to feedlot managers is how do you know when to ship your cattle?” says McCormack. “They’ll say ‘they look right,’ ‘they’ve gone across the scale,’ but really in terms of all the data they collect, it’s still very much a cultural and need-based decision. ‘They’ve been in the lot the longest,’ ‘they ‘look’ the most finished, so we’ll ship them.’ In reality, you may have 40 animals left in that pen that have another $200 left before their peak carcass quality.”

Average weight of the pen is another ‘readiness’ measurement, but that can still result in feedback sheets with some at AAA Prime, the optimum finish, but other discounts and ‘straggler’ diminishing overall returns.

McCormack explains Q-sort doesn’t add a lot of extra work or inputting of information (if a feed program is being used). When cattle are initially processed, it’s just a matter of collecting an extra tissue tag sample, and submitting it to Quantum. With the feeding program incorporated, the genetic data and economic comparisons are uploaded right into the app, and it’s then accessible to the producer.

“That’s the main point – it has to be simple. Within three clicks you can achieve this comparison scenario,” McCormack adds, noting that with a cost of three dollars per head, if you can feed the animal for one day less than planned, Q-sort pays for itself.

“It’s all about using genomics to enhance your operation,” says McCormack.

This article was first published in Volume 2 Issue 2 of ABP Magazine (April 2022). Watch for more digital content from the magazine on ABP Daily.