AB Direct - Steers

Rail: ---

AB Direct - Heifers

Rail: ---

US Trade- Steers

Rail: ---

US Trade - Heifers

Rail: ---

Canadian Dollar

0.35

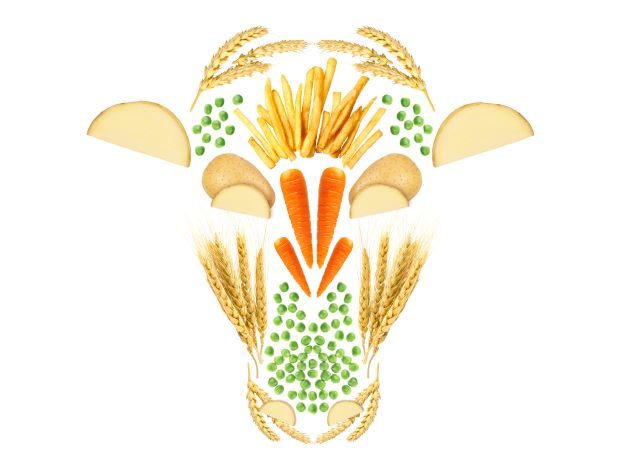

The ultimate upcyclers

Beef producers across western Canada are turning surplus food and food waste into high-quality protein by upcycling food that would otherwise go unused.

By forming relationships with food producers, processors and retailers, beef producers across Canada are helping convert a massive amount of human inedible food, plants and plant byproducts into high-quality protein – milk, eggs and meat – keeping it all out of landfills.

Creating value from surplus food and food waste is a movement that’s having a substantial impact, supporting environmental sustainability while lowering feed costs. “Livestock are uniquely positioned to upcycle relatively low-quality feedstuffs into high-quality protein. This makes them a valuable part of the food sustainability solution,” says Kim Ominski, professor in the Department of Animal Science, University of Manitoba.

The term ‘food waste’ tends to bring to mind scraps from dinner, but that’s not what’s being up-cycled at all. “What is going into livestock feed is not plate waste. Foods being used in this way usually result from harvest failures, crop pest problems, poor growing conditions such as frost, floods or drought, or production that exceeds storage capacity,” Ominski says.

For instance, more than 75 per cent of barley produced fails to meet the criteria for beer making, and a significant proportion of fresh produce fails to meet grading standards. These become sources for livestock feed. So does processed food that exceeds demand or storage capacity, and edible food past its shelf date. “What we call ‘food waste’ happens all along the supply chain, and most often it’s not related to excess production at all,” Ominski says.

Three kinds of relationships are supporting this progressive movement: producer-producer, processor-producer and retailer-producer.

Producer-producer

By forging relationships with other area food producers who have different needs and yields, beef producers are putting culled and excess produce to good use. “When there is an oversupply of greens or a large amount of misshapen carrots, these high-quality foods are usable, but not making it to the retailer,” says Ominski.

About 30 per cent of carrots grown have to be culled because they are crooked, malformed or bug marked. Many are donated to food banks, but there is a large amount of extra volume that makes nutritious cattle treats.

At Winkler, MB, Herman Peters, Nutrition and Agronomy Program Manager with Birkland Farms, adapted a grinder to break potatoes so they are less likely to cause choking. He works with local producers to add culled potatoes to rations at his feedlot year-round. “Our cows get 20 to 40 per cent of their diet from culled potatoes. They look at potatoes as candy once we start dropping them into the bunk,” Peters says.

Processor-producer

Coproducts from the processing of many field crops have been used as cattle feed for a long time. “Many of these products have high fibre content, which makes them a good food source. The rumen makes cattle uniquely positioned to use these, upcycling them into high-quality protein for the human diet,” says Ominski.

At its Portage la Prairie, MB pea protein processing plant, the largest of its kind in the world, Roquette converts coproducts, including pea hull pellets, screenings and pea cream, into food supplements for cattle, a system which became operational in 2022.

“The introduction of pea cream on the market in Manitoba is really a success. The product is currently used on 12 large farms, including dairy, beef and swine operations,” says Christian Delporte, Technical Support Manager with Roquette. “Due to the cost of transport, it’s more logical to use Roquette pea coproducts locally in Manitoba.”

Birkland Farms is using pea cream from Roquette, so it is unique in that they actually use multiple streams of food waste at the same time. “Roquette is a good example of how we can think differently about the byproducts of food processing as having a high value through alternate uses. Roquette actually describes these as coproducts, not byproducts. While the pea is the primary product, these secondary products they view as being equally important,” says Ominski.

In southern Alberta, Ryan Kasko with Kasko Cattle Company at Lethbridge, fed 50,000 tonnes of coproducts from the french fry making process to cattle over the course of one year. Working with a nutritionist, Kasko ensures the french fries are part of a balanced diet. “We mix in some grains, starch from french fries and also vitamins and minerals,” Kasko says. “If we can feed this to cattle rather than having it go into a landfill, I think we’re all winners.”

Retailer-producer

Retailers are also providing unsaleable grocery store food to cattle operations. Loop Resource out of Dawson Creek, B.C. supports relationship building between retailers and producers across Canada. Loop founder Jaime White initially worked with his local Co-op grocery store to supply unsaleable food for his own farm. He then created loopresource.ca to help grow food loops across the country, matching stores to farms based on size and diversity, and to charities whenever possible.

Loop currently serves more than 300 grocery stores and 2,700 farms across Canada, diverting three million kilograms of waste from landfills. Grocery chains participating include Co-op, Real Canadian Superstore and Save-On Foods.

Become an upcycler

The opportunity exists for beef producers across Canada to seek surplus and waste food sources to add to rations. Look for ways to diversify the product streams you rely on through relationships with producers, processors and retailers within a close radius of your operation. In every case, it’s best to use waste or surplus food close to its source, since the value is reduced through transportation.

There can be significant benefits to starting these kinds of relationships now, such as having alternate feed options in drought years, and reducing feed costs. “It doesn’t come without challenges, and there are extra costs to it, but obviously the economics work out, otherwise we wouldn’t be doing it,” Peters says.

The upcycling of surplus food points to the fact that livestock play an important role in a circular bioeconomy. “In a typical crop-livestock production system, livestock generate manure, manure improves soil quality on the landscape, which leads to increased crop yield, which goes back into the feeding of livestock. It’s a circular system,” Ominski concludes.

This article was first published in Volume 2 Issue 5 of ABP Magazine (December 2022). Watch for more digital content from the magazine on ABP Daily.